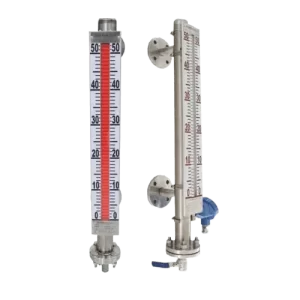

Mechanical Fuel Tank Level Indicator

A mechanical fuel tank level indicator is designed to provide accurate readings of fuel levels in storage tanks. It operates through a direct mechanical connection, typically using a float and lever system, which moves a pointer on a calibrated dial. This indicator is crucial for monitoring fuel levels in industrial, agricultural, and transportation sectors.

Description

The Mechanical Fuel Tank Level Indicator plays a vital role in monitoring and measuring fuel levels in storage tanks. Designed for both industrial and commercial use, it provides an efficient, hands-on solution for fuel management. Whether you are managing large machinery, generators, or transportation fleets, this device gives you accurate and real-time information on your fuel supply. Consequently, it allows for better fuel management, preventing shortages and overflows.

Key Features:

- High Accuracy: The Mechanical Fuel Tank Level Indicator ensures precise fuel readings, helping you avoid fuel-related issues that can disrupt operations.

- Durable Construction: Engineered to withstand harsh conditions, it is ideal for both indoor and outdoor installations. Thus, it remains reliable even in tough environments.

- Simple Operation: The indicator features an easy-to-read dial, enabling operators to quickly assess fuel levels without the need for complex systems. As a result, it simplifies fuel management.

- Maintenance-Free: This device requires minimal upkeep, reducing the cost and effort associated with routine maintenance.

- Versatile Applications: It serves a wide range of industries, from heavy machinery and industrial generators to transportation and fuel storage.

Benefits:

- Cost Efficiency: By providing accurate readings, the Mechanical Fuel Tank Level Indicator reduces fuel wastage and optimizes fuel consumption. This, in turn, lowers operational costs.

- Enhanced Safety: Regular monitoring helps prevent fuel shortages, overflows, and potential safety hazards. Therefore, it minimizes the risk of equipment downtime or accidents.

- Reliability: Unlike electronic systems, which may require battery replacements or technical support, the mechanical design offers long-term dependability with minimal maintenance needs.

Applications:

- Heavy Machinery: Ideal for construction and mining equipment, as well as agricultural machinery, the indicator ensures continuous operations by accurately monitoring fuel levels.

- Generators: Used in industrial backup power systems, this device helps maintain generator uptime by monitoring fuel levels in real time.

- Transportation: It supports fuel management in commercial vehicles like trucks, buses, and delivery fleets.

- Industrial Tanks: Perfect for use in various industries where fuel and oil storage require precise monitoring.