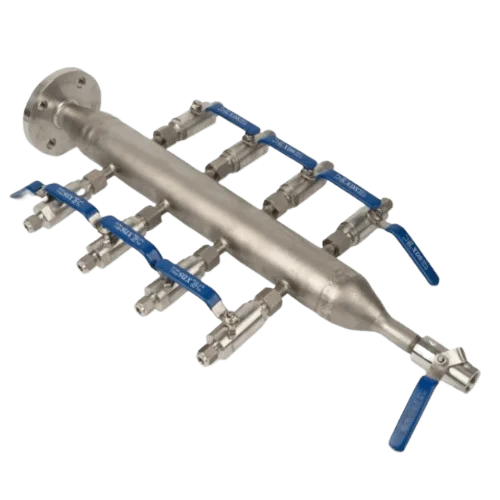

Distribution Manifold

Distribution manifolds, also known as air or steam headers, channel a single flow of gas, air, or liquid to several output points within a system. They also assist in draining excess fluids or condensation through vent valves, helping protect downstream equipment from corrosion and potential damage.

Description

Distribution Manifold valves actively control and direct fluid flow throughout industrial systems. They manage the movement of oil, gas, water, and chemicals across pipelines and equipment. Their capacity to manage different pressures and flow rates makes them essential for maintaining effective and dependable fluid control. As a result, industries such as oil & gas, chemical processing, and power generation depend on them for smooth and consistent operations.

Key Features

- Precise Flow Control: Distribution valves regulate fluid flow across multiple outlets or systems, ensuring optimal performance and preventing pressure imbalances.

- Durable Construction: Made from high-strength materials like stainless steel, distribution valves endure harsh environments, including high pressures, temperatures, and corrosive conditions.

- Versatile Design: Suitable for high- and low-pressure systems, these valves offer flexible solutions for diverse industrial needs.

- Leak-Proof Performance: Advanced sealing technology ensures minimal leakage, enhancing safety and efficiency in fluid management.

- Customizable Configurations: Available in various sizes, pressure ratings, and designs to meet specific application requirements.

Applications

Distribution Manifold Valves are used in various industries:

- Oil & Gas: Control the flow of oil, gas, and other fluids in pipelines, processing plants, and storage systems.

- Chemical Processing: Regulate the flow of chemicals and solvents during production and processing stages to ensure safe and efficient handling.

- Power Generation: Manage cooling fluids, steam, and other vital fluids in power plants to optimize energy production and system efficiency.

- Water Treatment: Control water flow across treatment facilities to maintain optimal system function.

Benefits

- Improved System Efficiency: Ensuring precise fluid flow helps optimize performance, reduce downtime, and improve reliability.

- Enhanced Safety: These valves reduce the risk of leaks and system failures, maintaining safe operations in critical industries.

- Durability: The rugged construction ensures effective performance in harsh environments, reducing maintenance and replacement costs.

- Cost-Effective: Optimizing fluid flow minimizes waste and energy consumption, lowering operational costs.

- Flexible Solutions: With various sizes and configurations, these valves can be customized to suit different system designs and industrial requirements.

Conclusion

Distribution Manifold Valves play a crucial role in fluid management across industries. Their ability to regulate flow in systems for oil & gas, chemical, power generation, and water treatment ensures operational efficiency, safety, and cost savings. Choosing reliable, well-built valves helps industries improve overall system efficiency and dependability.