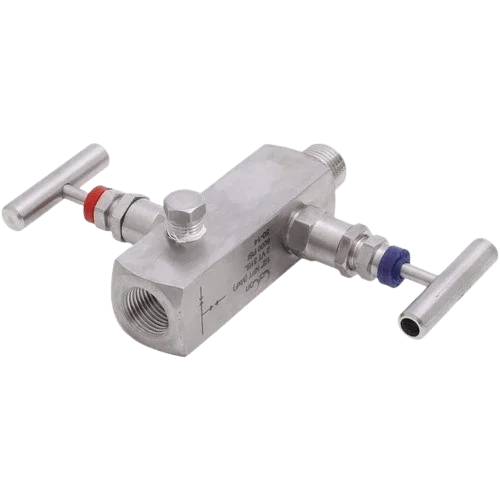

Block & Bleed Valve

A block and bleed valve is a type of valve assembly that allows for the isolation of a section of a system for maintenance or safety purposes. It typically features two block valves and a bleed valve in between, enabling operators to isolate pressure, vent it safely, and ensure the system is fully depressurized before any work is done. This design is commonly used in oil, gas, and petrochemical industries to prevent cross-contamination and ensure system integrity.

Description

Block & Bleed Valves are essential components in industrial applications where reliable flow isolation and pressure control are critical. These valves provide an effective solution for maintaining safe system operations in industries such as oil & gas, chemical, and power generation.

Key Features

- Flow Isolation: Block & Bleed valves allow for complete isolation of fluid flow, preventing leakage and ensuring safety during maintenance or operation changes.

- Pressure Control: These valves are designed to regulate pressure within a system, preventing dangerous overpressurization.

- Dual Functionality: Combines both blocking and bleeding features, allowing easy purging of trapped fluid and maintaining safe conditions.

- Durability: Built to withstand harsh conditions in demanding industries, these valves are resistant to corrosion, high pressure, and extreme temperatures.

- Ease of Use: Simple operation and maintenance reduce downtime and improve system efficiency.

Applications

Block & Bleed valves are widely used in:

- Oil & Gas: For flow control in pipelines, production facilities, and wellhead operations.

- Chemical Processing: Ensuring safe isolation and pressure regulation during chemical reactions and process changes.

- Power Generation: Protecting turbines, boilers, and other critical equipment from pressure fluctuations and fluid blockages.

Benefits

- Enhanced Safety: Provides reliable isolation to avoid accidental releases or pressure surges, ensuring the safety of personnel and equipment.

- Operational Efficiency: Reduces the need for complex and time-consuming maintenance procedures by integrating multiple functions into a single valve.

- Cost Savings: Minimizes downtime and maintenance costs while enhancing the reliability and longevity of your systems.

Why Choose Block & Bleed Valves?

Block & Bleed Valves stand out as a trusted solution in industries that require high reliability and safety. Their ability to isolate and bleed pressure efficiently reduces risk and increases operational uptime. By choosing high-quality valves from reputable manufacturers, you ensure that your systems are always secure and efficient.

Customization Options

Block & Bleed Valves come in various configurations to meet the unique demands of different applications. Customizable features such as valve size, material, and pressure rating ensure that these valves fit perfectly with your specific requirements. Work with trusted suppliers to tailor the solution for optimal performance in your facility.

Conclusion

Whether in oil & gas, chemical, or power industries, Block & Bleed Valves are a reliable, cost-effective solution for managing fluid flow and pressure. Their robust design and versatile functionality make them a crucial component in maintaining system integrity and operational safety.