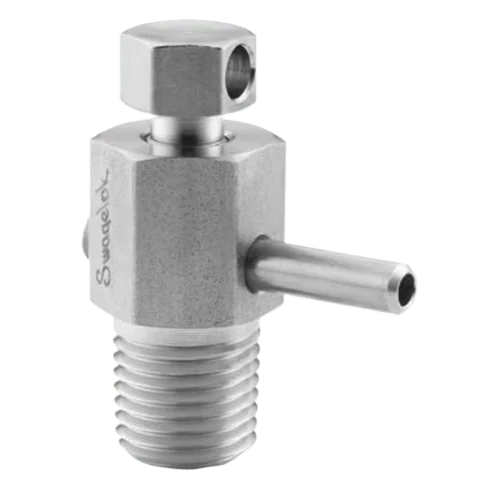

Bleed Valve

A bleed screw is a component that allows temporary access to a closed hydraulic system to release trapped air or other substances, using pressure and density differences to aid the process. Available in ¼” and ½” sizes.

Description

A bleed valve is a crucial component in fluid and gas systems. It releases trapped pressure, air, or fluid from pipelines, tanks, or equipment to maintain safety and efficiency. These valves help safeguard key components and improve system efficiency by providing precise pressure release.. Industries such as oil and gas, chemical processing, power generation, and water treatment widely rely on these valves for their reliability and functionality.

Key Features

- Pressure Relief: Bleed valves safely release excess pressure to prevent equipment damage and maintain stability.

- Compact Design: Their small and efficient design simplifies installation, especially in tight spaces.

- Corrosion Resistance: Constructed from durable materials like stainless steel or brass, these valves withstand harsh conditions.

- Ease of Operation: Many bleed valves come with user-friendly mechanisms, allowing quick and precise pressure control.

- Leak Prevention: High-quality sealing ensures reliable performance without leaks.

Applications

- Oil and Gas: They release pressure in pipelines, safeguarding equipment in high-pressure systems.

- Chemical Processing: These valves control pressure during the transport and storage of reactive chemicals.

- Water Treatment: They efficiently remove trapped air from pipelines, improving water flow.

- Power Generation: Bleed valves regulate pressure in boilers and turbines, ensuring safe and efficient energy production.

- Industrial Equipment: They help protect sensitive instruments by releasing excess pressure during operations.

Benefits

Bleed valves offer multiple benefits that contribute to improved overall system efficiency and reliability. For instance, they prevent over-pressurization, which, in turn, reduces the risk of accidents and equipment damage. Furthermore, these valves improve system efficiency by eliminating trapped air or fluid that could otherwise disrupt operations. Moreover, their durable design requires minimal maintenance, thereby saving time and costs. Finally, with their compact and versatile design, bleed valves seamlessly adapt to various applications, offering unmatched flexibility.

Conclusion

Bleed valves play a vital role in maintaining pressure regulation and ensuring system safety in a wide range of industrial applications. Their ability to combine reliability, durability, and efficiency makes them a trusted solution for industrial applications. By using bleed valves, businesses can enhance safety, improve system performance, and reduce operational risks, ensuring smooth and trouble-free operations.